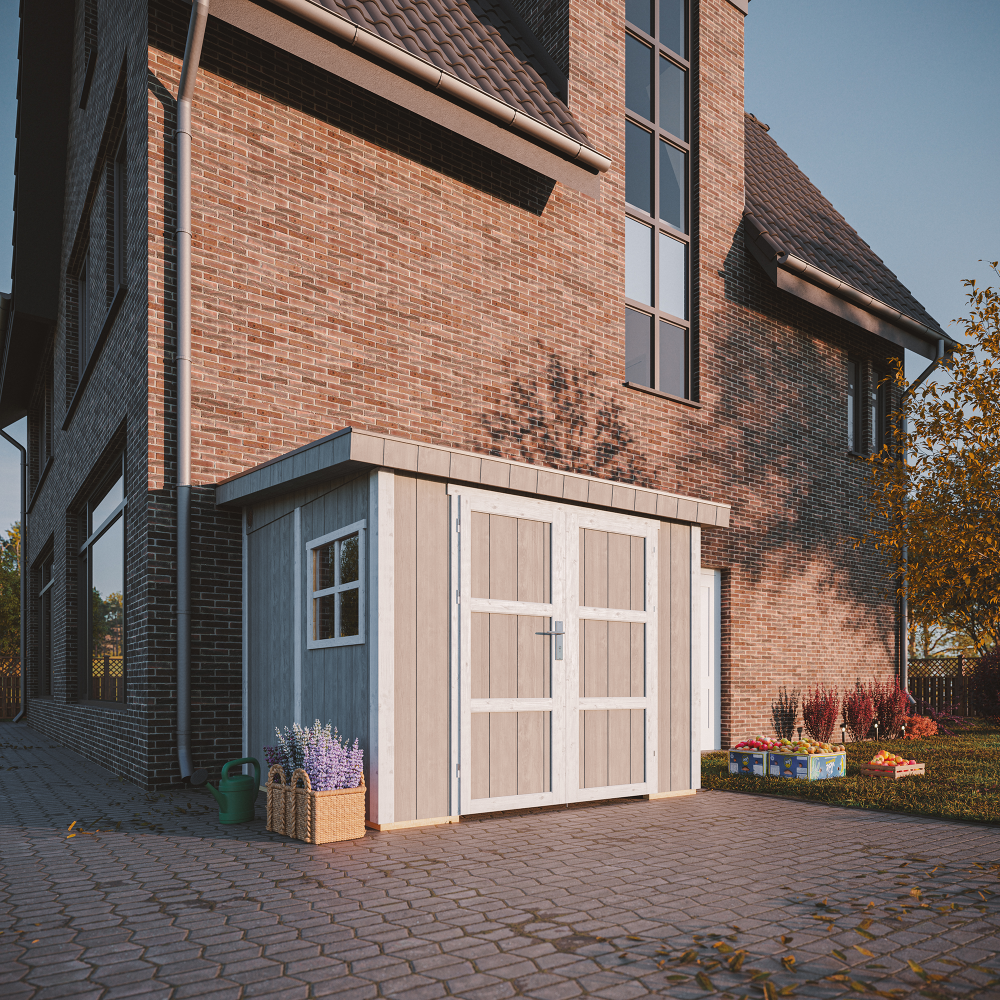

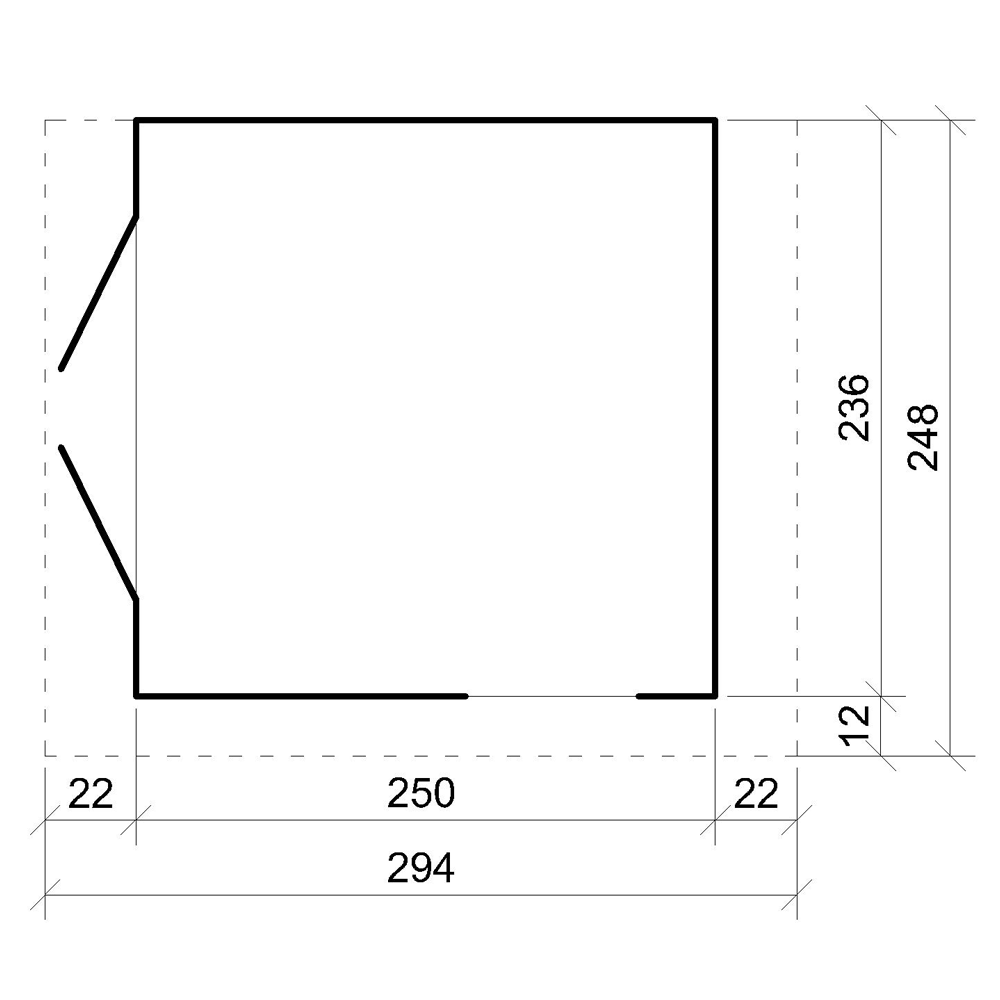

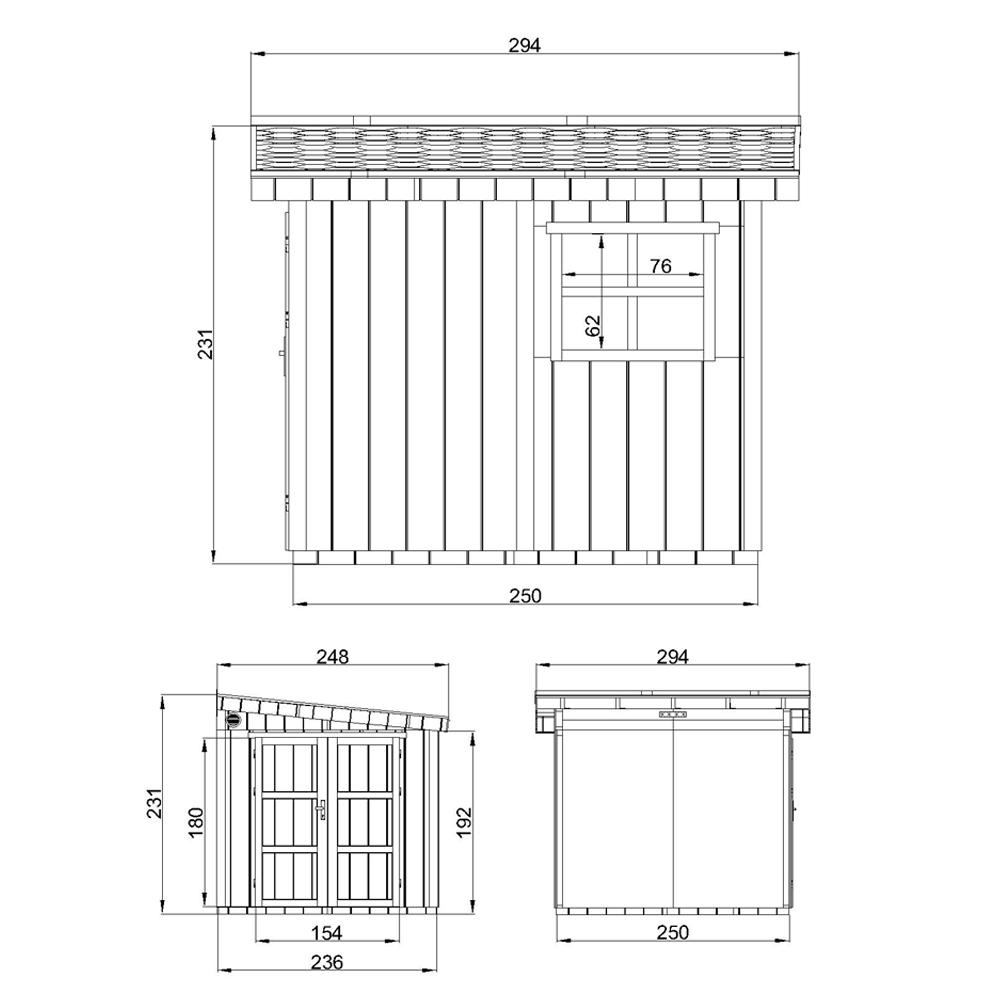

LP® SmartSide® panel shed M938 – 236 x 250 cm – 6 m2

Modern and minimalist LP® SmartSide® garden shed – a practical and organized space for storing garden tools, bicycles, small equipment, or children’s toys.

Exceptional durability: LP® SmartSide® panels are resistant to environmental factors, deformation, mold, insects, and rot. Their strength is ensured by four core components – resins, wax, zinc, and a primed protective coating.

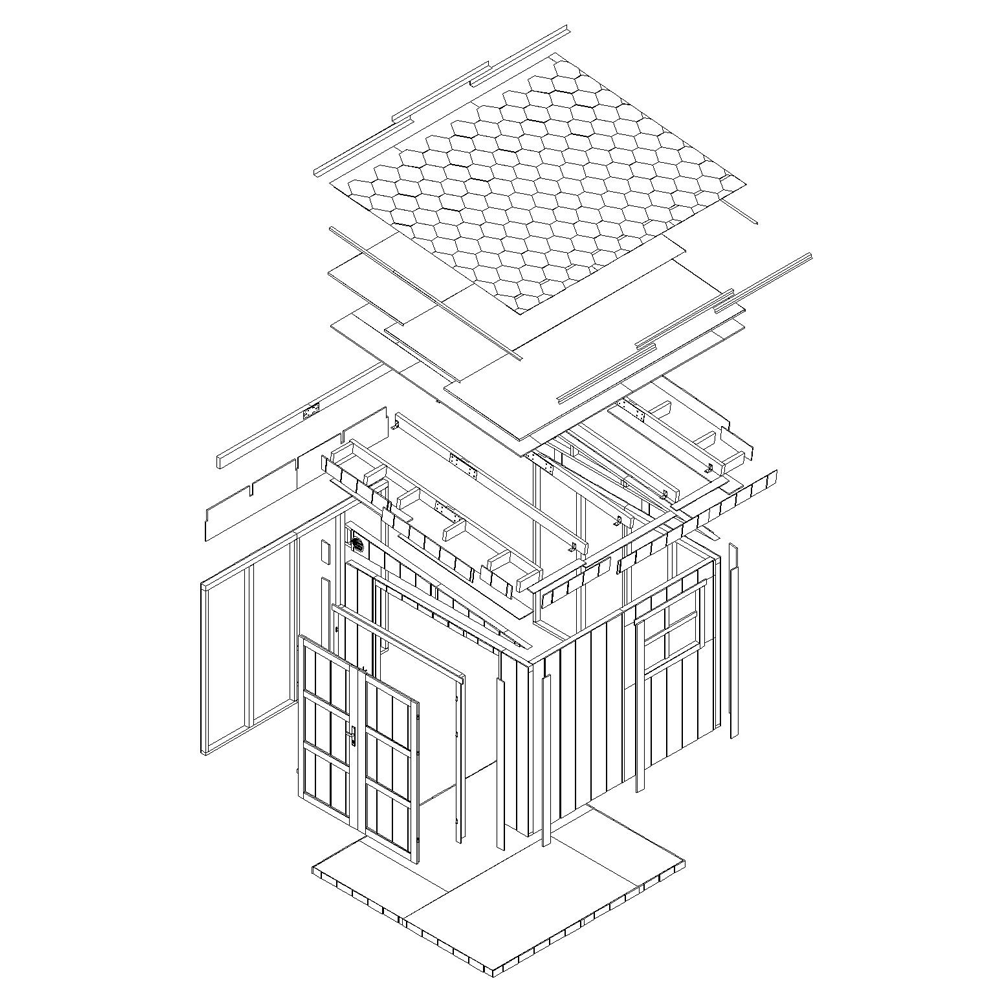

Sturdy panel construction: The shed walls are built from a 60×60 mm wooden frame and 10 mm thick LP® SmartSide® panels with a primed coating – providing durability and structural stability even in challenging weather conditions.

All-in-one package: The shed comes complete with grey bitumen shingles for the roof. Integrated ventilation grilles ensure proper airflow inside the structure.

Paint options: The product is available with an acrylic-based paint kit specifically designed for LP® SmartSide® panels. The kit includes 2 liters of your selected wall panel color and 1 liter of white paint for the wooden trim. Wall panels and wooden trims must be treated! The shed is sold unpainted.

LP® SmartSide® Cladding Panels

LP® SmartSide® panels are manufactured using the advanced SmartGuard® process. Thanks to four protective components, this technology significantly increases panel durability and helps LP® SmartSide® products withstand warping, temperature fluctuations, high humidity, and other harmful external factors.

The production process uses additives such as: resins, waxes, zinc borate, and a primed coating.

| 01

Zinc borate – this naturally sourced additive protects the panels from fungi and pests. The panels contain a triple dose of zinc borate, which is safe for humans but effectively prevents pest activity.

|

02

Resins – the panels are coated with marine-grade epoxy resin to provide exceptional resistance to strong impacts and sudden temperature changes.

|

| 03

Wax – waterproof wax coats every wood strand, creating a protective barrier resistant to rain, snow, and moisture.

|

04

Primed coating – the final protective layer shields the panel from moisture and provides a durable base for high-quality painting.

|

|

|

||||

|

|

||||

|

|

Material: 10 mm thick LP SmartSide wood-based panels

Ventilation grilles

15 mm LP® ProStruct® flooring with SmartFinish® coating

Wooden corner finishing elements

Side wall: water-resistant OSB-3 (12 mm)

Windows: 1 glass window, 62 x 76 cm

Double doors: 154 x 180 cm with lock

Grey metal drip edge

Roof made of water-resistant OSB-3 plywood (12 mm)

Assembly kit (screws, hinges)

Assembly instruction

OPTIONAL: set of paints of the selected color

LP® SmartSide® cladding panels absorb more greenhouse gases over their lifetime than are emitted during the manufacturing process.

LP® SmartSide® panels go beyond carbon neutrality – their carbon footprint (CO2) is negative.

LP® SmartSide® is made of 91% wood strands sourced from sustainably managed forests.

|

The board is produced from a natural and rapidly renewable resource – wood.

|

In the manufacturing process, we efficiently use 99% of the wood. It is used either as raw material for products or as a renewable energy source in the factory.

|

|

We make every effort to ensure that 100% of the wood used in our production comes from responsibly managed forests. This material is fully traceable at every stage of production and trade – from the forest manager all the way to the final product manufacturer. |

|

LP® SmartSide® panels are designed to be highly resistant to environmental impact, but proper maintenance is essential to ensure their longevity and appearance. Once a year, inspect the surface for any signs of peeling, fading, or chalking paint. Pay special attention to the bottom row of panels and repaint if necessary. Always use acrylic-based paints.

For cleaning, use a soft cloth or gentle brush, followed by a rinse with clean water. Do not use bleach or ammonia-based cleaners. DO NOT use high-pressure washers, as the pressure may damage the paint and force moisture into the inner layers.

The LP® SmartSide® panel comes with 15-year warranty, the LP® ProStruct® floor panel comes with 10-year warranty The guarantee starts on the date of invoicing. The warranty is valid only when the product is assembled following the assembly instructions. The warranty only covers the replacement of defective parts! All parts are delivered in their natural state and must be treated following the instructions.

To avoid possible mistakes when assembling the hut, we recommend checking the product parts list and sorting the parts before installation. This check must be carried out within 14 days from the date of purchase. The warranty only applies to defective parts that have not yet been installed in the product. Defective parts that have already been treated and used in the product are not covered by the warranty!

In order to benefit from this guarantee, the Buyer must inform the Seller in writing of any damage or defect in the Goods at sale@timbela.com. In the event of a defect or damage to the goods, the Buyer must provide detailed photographs of the goods and a list of the damaged (defective) parts. Please also include the LOT number indicated in the installation instructions.

Product manufacturer: Timbela ir Ko

Address: Ryternos g. 3B-2, Biruliškės, LT-54469, Lithuania

Email: sale@timbela.com

All products are packed on pallets and delivered by heavy goods vehicles equipped with lifts.

Order is delivered as close to the house as possible! If a large vehicle cannot enter the yard, the load is unloaded where access is available, so make sure that a large truck can reach your home before purchasing the product. The product is delivered to the Buyer unassembled. The parts are packed on a pallet, protected by a black film and additional plating.

Telephone number REQUIRED for delivery. If the buyer cannot be contacted, the courier will not be able to deliver the goods!

The product you have purchased is manufactured, tested, and packaged according to high-quality standards and controls.

We recommend:

– Store the packaged product in a dry, dark place without direct contact with the ground.

– Protect from sun and moisture.

Please read the instructions carefully before starting to assemble the shed to avoid any mistakes when assembling and using the product you have purchased.

Check that the packaging contains all the parts mentioned in the instructions and sort them.

We recommended to paint one coat before assembly, first the ends of floor panels and the ends of all wall panels. The vertical trim boards we also recommended to paint one coat before assembly. When you assemble the wall panels, for soffit and fascia trims we recommend to paint one coat and after assembly the vertical trim to paint second coat all panels and trims.

Before assembling, please check that the surface on which you intend to build the hut is level. We recommend having a hard, moisture-resistant surface, such as concrete paving, paving units, or foundations. Do not build your wooden hut on grass or soil!

When choosing a spot for the hut, please make sure the hut will not be exposed to extreme weather conditions (strong winds or snow). Otherwise, you should additionally use anchors.

Before starting assembly, carefully read the entire manual and keep it for future reference. Ensure the product is installed on a level, stable surface, as proper base preparation is essential for safe assembly and long-term durability. Before assembling, check and sort all parts, and store them in a dry, protected area off the ground. Assembly is recommended with at least two people and appropriate safety equipment.

Follow the step-by-step instructions, beginning with a properly leveled base, then installing the floor (if included), walls, roof structure, and roofing materials. Do not overtighten fasteners and, where necessary, pre-drill to prevent wood splitting. The roof covering should be installed immediately after assembly to protect the structure from moisture.

After assembly, apply suitable protective treatment such as exterior paint or stain according to recommendations. Inspect the product annually and maintain it as needed. Please note that wood is a natural material and may expand, shrink, or develop minor cracks due to weather conditions—this is normal and does not affect structural performance.